In modern warehouses, factories, and logistics operations, efficiency and safety in material handling are crucial. The adjustable hydraulic pallet fork frame has become a key solution for businesses that require flexibility, reliability, and precise load management. Designed to adapt to various pallet sizes and load types, this versatile equipment enhances forklift capabilities while improving operational productivity.

By integrating hydraulic adjustment mechanisms, operators can quickly modify fork spacing and alignment, ensuring safer lifting and transport of materials in industrial environments.

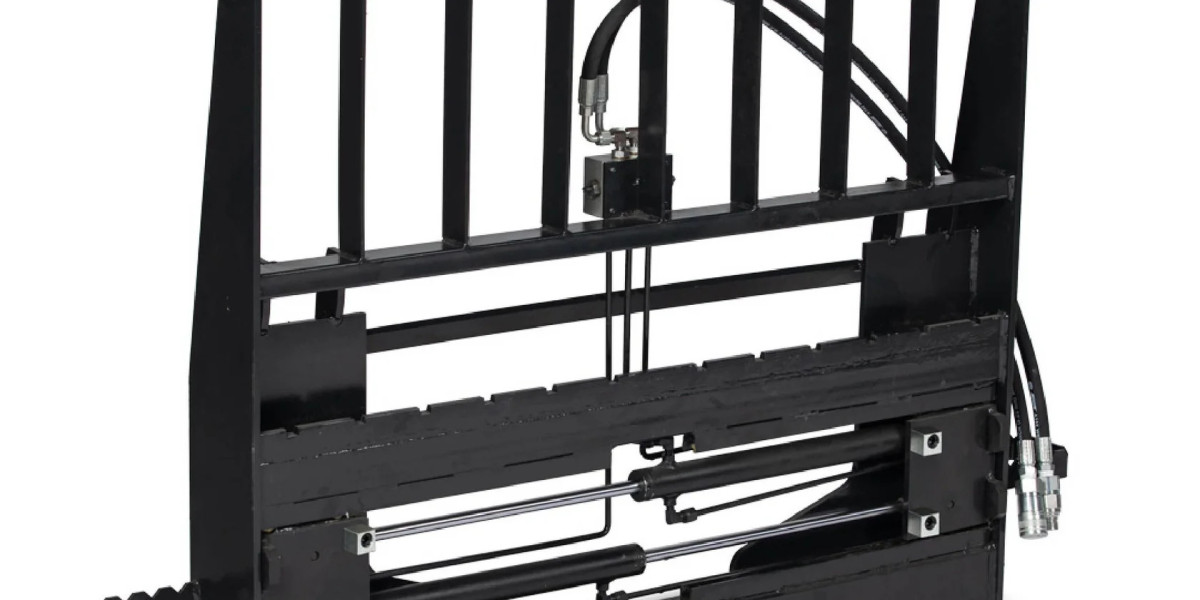

What Is a Adjustable Hydraulic Pallet Fork Frame

A adjustable hydraulic pallet fork frame is an attachment for forklifts that allows the width between forks to be adjusted hydraulically. This feature enables forklifts to handle different pallet sizes and types without manual adjustments, reducing downtime and labor costs.

Key Components Include:

Hydraulic Cylinders: Enable smooth and precise adjustment of fork spacing.

Fork Arms: Heavy-duty steel construction ensures durability and load stability.

Mounting Frame: Designed for secure attachment to standard forklift carriages.

Control System: Hydraulic levers or joystick control allow operators to adjust fork width safely and efficiently.

Key Features and Benefits

Flexible Load Handling

Adjust fork spacing hydraulically to fit different pallet sizes.

Ideal for mixed-load operations, reducing the need for multiple forklift attachments.

Enhanced Safety

Hydraulic adjustment reduces manual handling and the risk of injury.

Secure fork locking ensures loads remain stable during lifting and transport.

Durable and Reliable Construction

Heavy-duty steel frame resists bending and deformation under high loads.

Hydraulic components designed for long-term industrial use with minimal maintenance.

Increased Operational Efficiency

Rapid fork adjustment saves time when switching between pallet types.

Reduces downtime and labor costs by eliminating manual repositioning of forks.

Versatile Applications

Suitable for warehouses, shipping yards, manufacturing plants, and distribution centers.

Handles a wide range of load types, from standard pallets to oversized crates and containers.

Advantages Over Fixed Fork Frames

Adaptability: Handles multiple pallet sizes with a single frame.

Reduced Labor: Hydraulic adjustment eliminates the need for manual repositioning.

Improved Safety: Secure load management minimizes accidents and load slippage.

Durability: High-quality materials and hydraulic systems ensure long-term performance.

Cost Efficiency: One adjustable frame replaces multiple fixed frames, reducing capital investment.

Applications Across Industries

Warehousing and Logistics

Efficiently handles pallets of various sizes, speeding up loading and unloading operations.

Manufacturing Plants

Moves raw materials, semi-finished goods, and finished products safely between production lines and storage areas.

Distribution Centers

Flexible handling of mixed shipments reduces operational delays and increases throughput.

Construction Sites

Transports building materials, crates, and equipment safely over short distances.

Food and Beverage Industry

Handles pallets of packaged goods, beverages, and refrigerated items without compromising load stability.

Installation and Maintenance

Installation: Easy attachment to standard forklift carriages using secure mounting points. Ensure hydraulic connections are properly sealed and checked for leaks.

Operation: Adjust fork spacing using hydraulic levers or joystick controls; always follow manufacturer’s safety instructions.

Maintenance: Regularly inspect hydraulic cylinders, hoses, and seals. Lubricate moving parts and check for any structural damage to maintain safe and efficient operation.

Proper installation and maintenance ensure long-term reliability and safety of the adjustable hydraulic pallet fork frame.

Conclusion

The adjustable hydraulic pallet fork frame is a versatile and reliable solution for modern material handling challenges. By providing flexible fork spacing, durable construction, and hydraulic control, it enhances operational efficiency, ensures safety, and reduces labor costs.

Investing in a PABREAK adjustable hydraulic pallet fork frame allows warehouses, factories, and distribution centers to handle diverse load types efficiently, improve productivity, and maintain safe operations. This attachment is an essential tool for businesses seeking smarter, more adaptable material handling solutions.